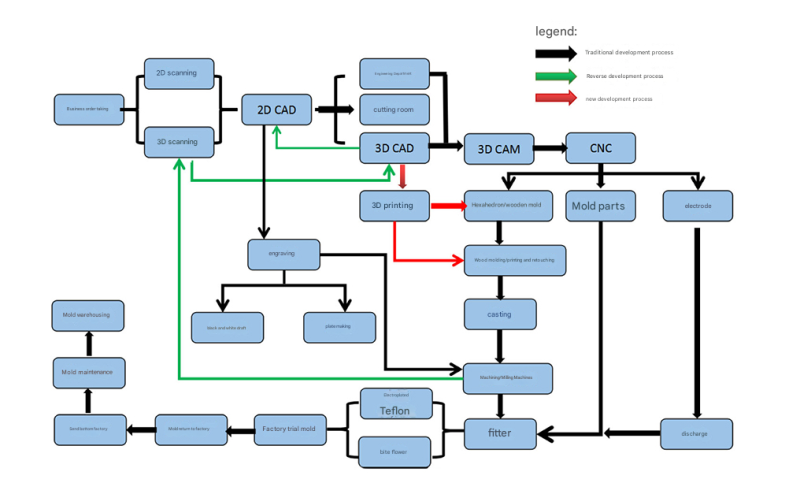

Introduction to the Molding Process

The general process of mold manufacturing refers to the entire sequence of activities that transforms product information provided by users into a functional mold. This comprehensive molding process involves analyzing product usage and structure, conducting manufacturability analysis for the molding process, designing 3D models of the mold, generating engineering drawings, machining individual mold components, and finally assembling them into a production-ready mold.

The mold manufacturing process is a direct continuation of the design process, translating blueprints and 3D models into physical components that are then assembled into a working mold. Properly determining the processing content, nature, and methods for mold components, especially establishing the optimal combination of machining processes for each surface, is crucial for optimizing efficiency, reducing costs, and ensuring the final product meets design specifications.

The complete molding process can be divided into five distinct stages: technical preparation, pre-processing preparation, mold component processing, assembly/repair/testing, and final inspection and acceptance. These stages are interconnected and build upon each other to create a high-quality, functional mold.

Key Learning Objectives

- Understanding the complete molding process from design to production

- Recognizing common processing technologies and equipment for mold components

- Classifying different types of mold components and their specific requirements

- Understanding machining precision capabilities of various equipment

- Selecting appropriate processing methods and equipment for specific tasks

- Mastering component processing process planning for the molding process

- Learning specific processing technologies including conventional machining, CNC machining, special processing, and surface treatment

Knowledge Framework

1. Technical Preparation Stage

The technical preparation stage forms the foundation of the entire molding process, serving as the primary basis for subsequent component processing. This critical phase significantly impacts mold manufacturing quality, cost, schedule, and overall management. A well-executed technical preparation phase ensures that the subsequent molding process proceeds efficiently and produces high-quality results.

Thorough technical preparation is essential for optimizing the molding process, as it establishes the parameters and procedures that guide all subsequent manufacturing activities. Without proper technical preparation, the molding process can encounter costly delays, quality issues, and inefficiencies.

Product Analysis

Analysis of product component structure, dimensional accuracy, surface quality requirements, and forming processes based on part drawings and specifications, culminating in comprehensive documentation.

Mold Design

Creation of mold CAD models and generation of related drawings based on part requirements and forming processes, establishing the blueprint for the entire molding process.

Process Documentation

Development of technical documents for mold component processing, material and processing time quotas, mold cost estimation, all critical for managing the molding process efficiently.

Programming

Writing of NC and CNC machining programs based on mold component structure characteristics, ensuring precision execution of the molding process through computer-controlled machinery.

During the technical preparation stage, engineers must consider not only the functional requirements of the final product but also the practicalities of the molding process. This includes evaluating material properties, machining capabilities, and quality control measures that will be implemented throughout the manufacturing cycle.

The technical preparation phase often involves close collaboration between design engineers, manufacturing specialists, and quality assurance personnel to ensure that the planned molding process will meet all specifications while remaining cost-effective and efficient.

Engineers use advanced CAD software to design molds during the technical preparation phase of the molding process

Critical Considerations

- Material selection must align with molding process requirements

- Tolerance analysis ensures parts will fit together properly

- Process planning must account for equipment capabilities

- Cost estimation should include all stages of the molding process

- Documentation must be clear for all subsequent manufacturing steps

2. Pre-Processing Preparation Stage

The pre-processing preparation stage bridges the gap between technical planning and actual manufacturing in the molding process. This phase ensures that all necessary materials, tools, and components are available and properly prepared before machining operations begin, which is essential for maintaining efficiency and quality throughout the molding process.

Effective pre-processing preparation minimizes downtime during the actual manufacturing phase, as machines and operators can focus on production rather than searching for materials or tools. This stage is critical for maintaining the schedule established during technical preparation and ensuring that the molding process proceeds smoothly.

Key Activities in Pre-Processing Preparation

Blank Preparation

Acquisition and preparation of raw material blanks according to specified types, forms, sizes, and technical requirements. For plate-type components, suppliers often perform initial rough machining, which is factored into subsequent process planning.

Electrode Material Preparation

Procurement and preparation of electrode materials based on processing requirements, particularly important for EDM (Electrical Discharge Machining) operations in the molding process.

Standard Component Procurement

Ordering of standard mold components and parts based on design specifications. This includes items like guide pillars, bushings, ejector pins, and other standardized elements that don't require custom manufacturing.

Tooling and Fixture Preparation

Preparation of appropriate cutting tools, fixtures, and other auxiliary equipment based on the established processing technology. This ensures that each machine is properly equipped for its role in the molding process.

The pre-processing preparation stage requires careful coordination between purchasing, storage, and manufacturing departments. Effective inventory management ensures that materials are available when needed without excessive stockpiling, which ties up capital unnecessarily.

In modern mold manufacturing facilities, digital inventory systems often track materials and tools, providing real-time visibility into availability and ensuring that the pre-processing stage efficiently supports the upcoming molding process. This integration of technology helps minimize waste and maximize productivity throughout the manufacturing cycle.

Material Requirements Planning

Properly prepared materials and blanks ready for the molding process

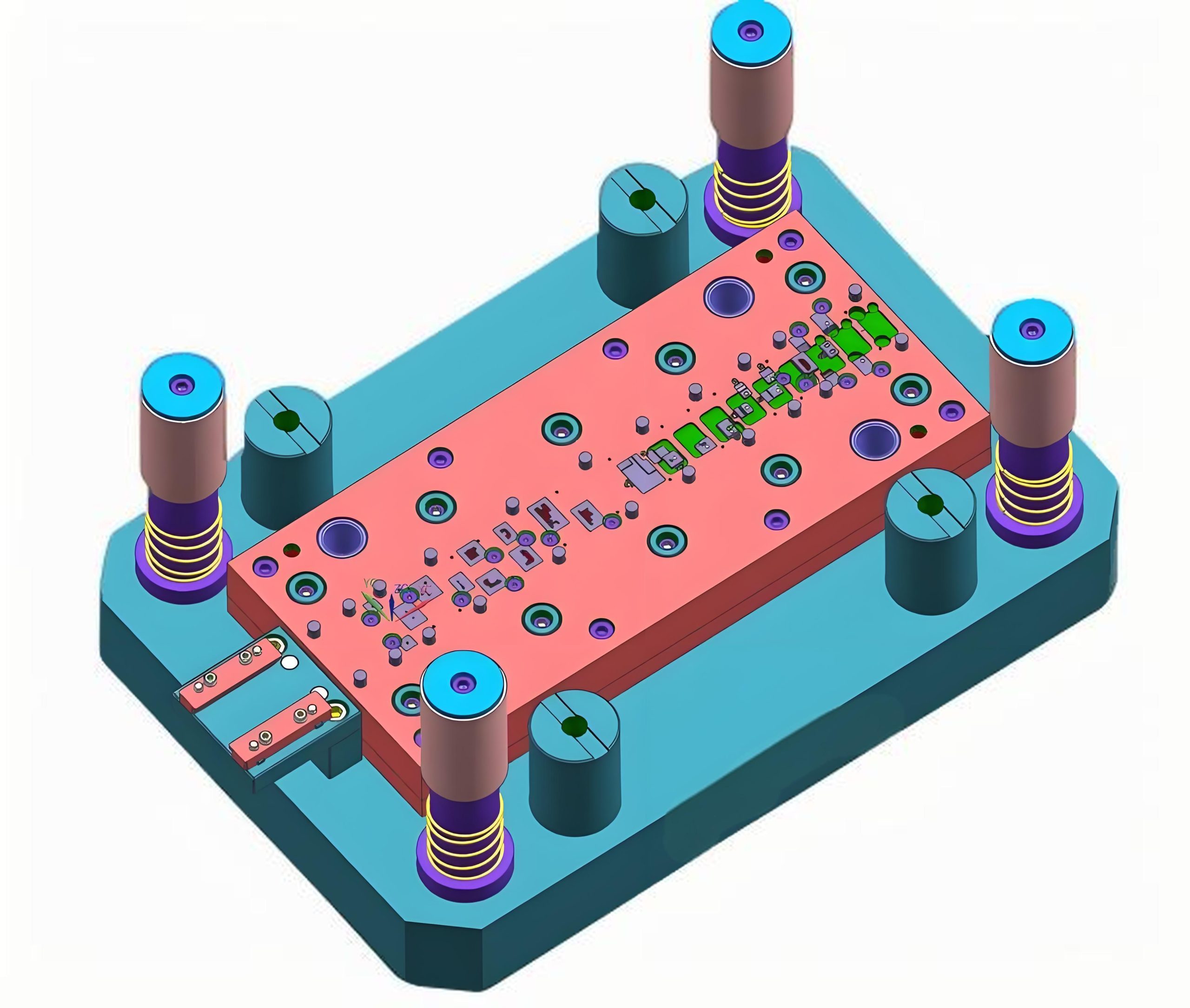

3. Mold Component Processing Stage

The mold component processing stage represents the most critical and labor-intensive phase of the entire molding process. This is where raw materials are transformed into precise mold components through various machining operations, each carefully selected to achieve the required dimensions, surface finishes, and mechanical properties. The quality of work performed during this stage directly impacts the final performance and longevity of the mold, making it central to the overall molding process.

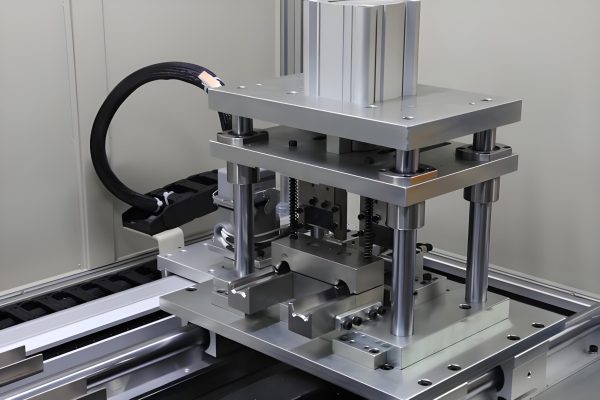

Advanced CNC machining centers play a crucial role in the modern molding process, delivering precision and efficiency

Processing Technologies in the Molding Process

Conventional Machining

Traditional machining methods form the foundation of many mold manufacturing operations in the molding process. These techniques include:

- Turning: Creating cylindrical parts on lathes, used for shafts, bushings, and other rotational components

- Milling: Removing material with rotary cutters to create complex shapes and features

- Drilling: Creating holes of various sizes and depths using drill bits

- Grinding: Achieving high precision and surface finish using abrasive wheels

- Planing and Shaping: Creating flat surfaces and grooves with linear cutting motions

While automated methods have largely replaced manual operation, these fundamental processes remain essential in the molding process.

CNC Machining

Computer Numerical Control (CNC) machining has revolutionized the molding process, offering unparalleled precision, repeatability, and complexity in component manufacturing:

- 3-Axis Milling: For simple to moderately complex 3D shapes and profiles

- 5-Axis Machining: For highly complex geometries requiring simultaneous movement along multiple axes

- Wire EDM: Precision cutting using electrical discharges through a thin wire electrode

- Sinker EDM: Creating complex cavities using shaped electrodes submerged in dielectric fluid

- CNC Turning: Automated lathe operations with live tooling for complex rotational parts

CNC technology enables the production of complex mold components with tight tolerances essential to the molding process.

Special Processing Technologies

Certain mold components require specialized processing techniques beyond conventional and CNC methods in the molding process:

- Electrochemical Machining (ECM): Using electrolysis to shape metal without mechanical contact

- Ultrasonic Machining: Using high-frequency vibrations with abrasive slurry for hard materials

- Laser Processing: Precise cutting, drilling, and marking using focused laser beams

- Water Jet Cutting: Abrasive water jets for cutting complex shapes in various materials

- Photochemical Machining: Chemical etching guided by photoresist masks for precision parts

These specialized techniques expand the capabilities of the molding process, allowing for features that would be impossible with conventional methods.

Surface Treatment Technologies

Surface treatments are critical in the molding process to enhance performance, durability, and functionality of mold components:

- Heat Treatment: Hardening, tempering, and annealing to optimize mechanical properties

- Plating: Applying metal coatings (chrome, nickel) for wear resistance and release properties

- Nitriding: Diffusing nitrogen into surface layers to create hard, wear-resistant surfaces

- Polishing: Achieving specified surface finishes to improve part quality and mold release

- Coatings: Applying specialized non-stick or wear-resistant coatings for specific molding process requirements

Proper surface treatment significantly extends mold life and improves the quality of parts produced through the molding process.

Processing Sequence in the Molding Process

Rough Machining

Initial removal of excess material to create approximate shape, establishing basic dimensions while leaving sufficient stock for subsequent operations in the molding process.

Heat Treatment

Controlled heating and cooling to achieve desired material properties such as hardness, often performed after rough machining to minimize distortion in the molding process.

Semi-Finishing

Further refinement of dimensions and surfaces, bringing components closer to final specifications while maintaining some stock for finishing operations in the molding process.

Final Heat Treatment (if required)

Additional thermal processing to achieve final material properties, sometimes applied after semi-finishing in critical areas of the molding process.

Finishing Operations

Precision machining to achieve final dimensions, tolerances, and surface finishes, often utilizing the most accurate equipment in the molding process.

Surface Treatment

Application of final surface treatments to enhance performance characteristics critical to the functionality of the completed mold in the molding process.

Machining Accuracy Comparison

| Processing Method | Typical Tolerance | Surface Finish (Ra) | Common Applications |

|---|---|---|---|

| Turning/Milling | ±0.01-0.1 mm | 1.6-6.3 μm | General mold components, non-critical surfaces |

| Grinding | ±0.001-0.01 mm | 0.025-0.8 μm | Guideways, precision mating surfaces |

| CNC Milling | ±0.005-0.02 mm | 0.8-3.2 μm | Complex 3D surfaces, cavities |

| Wire EDM | ±0.001-0.005 mm | 0.4-1.6 μm | Precision slots, complex profiles |

| Sinker EDM | ±0.002-0.01 mm | 0.8-3.2 μm | Complex cavities, intricate shapes |

| Lapping/Polishing | ±0.0005-0.002 mm | 0.008-0.1 μm | Critical surfaces, optical quality finishes |

Selecting the appropriate processing method based on these characteristics is essential for optimizing both quality and cost in the molding process.

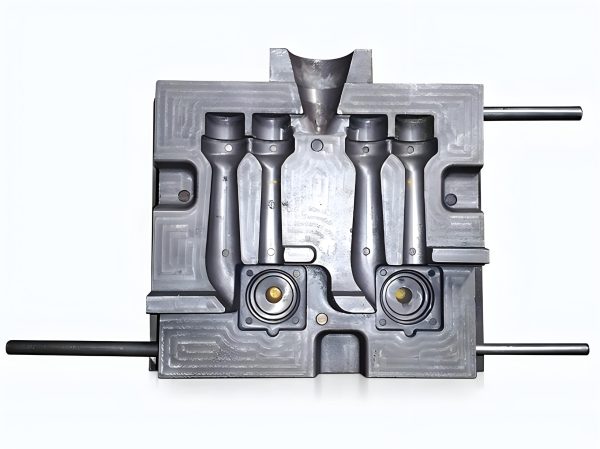

4. Assembly, Repair, and Testing Stage

The assembly, repair, and testing stage is where individual components come together to form a functional mold, marking a critical transition in the molding process from individual parts to a complete system. This phase verifies that all components work together as designed and ensures the final mold meets all performance requirements before it enters production.

While advances in machining precision have reduced the need for extensive fitting and adjustment, the assembly stage remains vital in the molding process to address any cumulative tolerances and ensure proper functionality of the complete mold system.

Assembly Process in the Molding Process

-

1

Component Inspection

Verification of dimensional accuracy, positional accuracy, and surface roughness of all components against design specifications before assembly begins.

-

2

Sub-Assembly

Assembly of related components into sub-systems (e.g., core assemblies, cavity assemblies, ejection systems) to simplify final assembly and ensure proper functionality of each sub-system.

-

3

Final Assembly

Integration of sub-assemblies into the complete mold according to assembly drawings and specifications, following the proper sequence to avoid damage to components.

-

4

Fitting and Adjustment

Precision fitting of components where necessary, including minor adjustments to ensure proper clearances, alignment, and movement throughout the mold.

-

5

Function Testing

Verification of all moving parts, including ejection systems, slides, and cooling channels, to ensure proper operation before mold testing begins.

Modern mold assembly often utilizes precision fixtures and jigs to ensure accurate positioning of components during the assembly process. This helps maintain the tight tolerances required for effective mold performance in the molding process.

Proper documentation during assembly is also critical, as it provides a record of any adjustments made and serves as a reference for future maintenance or repair of the mold throughout its production life in the molding process.

Mold Testing and Repair in the Molding Process

Mold testing, often called "tryout," is a critical phase that validates the entire molding process, ensuring the mold produces parts that meet all design specifications:

Preparation for Testing

The mold is mounted on an appropriate molding machine, and all connections (cooling, hydraulic, electrical) are properly established according to the molding process requirements.

Initial Test Runs

Preliminary molding runs to verify basic functionality, including proper filling, cooling, and ejection without catastrophic failure.

Process Optimization

Adjustment of molding parameters (temperature, pressure, cycle time) to optimize part quality and production efficiency in the molding process.

Part Inspection

Detailed measurement and evaluation of test parts to check dimensional accuracy, surface quality, and overall part quality against design requirements.

Mold Evaluation

Assessment of mold performance, including cycle time, reliability, and ease of operation during the molding process.

Repair and Modification

Addressing any issues identified during testing through targeted repairs or modifications to improve mold performance and part quality.

Final Validation

Conducting additional test runs after modifications to confirm that all issues have been resolved and the mold performs as required in the molding process.

Mold testing in the actual production environment ensures proper performance in the molding process

Common Issues Identified During Mold Testing

Filling Issues

Incomplete filling, flow lines, or air traps that indicate problems with gate design, runner system, or mold geometry in the molding process.

Dimensional Problems

Parts not meeting dimensional specifications due to improper shrinkage control, warpage, or mold deflection during the molding process.

Surface Defects

Poor surface finish, including scratches, marks, or improper texture resulting from mold surface issues or processing parameters.

Ejection Problems

Difficulties in removing parts from the mold, including sticking, damage during ejection, or uneven ejection forces.

Cooling Issues

Uneven cooling, excessive cycle times, or part distortion due to inadequate or poorly designed cooling systems in the mold.

Mechanical Problems

Issues with moving components such as slides, lifters, or ejection systems not functioning properly during the molding process.

5. Mold Inspection and Acceptance Stage

Precision inspection ensures molds meet all specifications before acceptance

Acceptance Criteria Checklist

- Dimensional accuracy of all components

- Surface quality meets specified requirements

- Functional performance during testing

- Produced parts meet design specifications

- Cycle time meets production requirements

- Documentation is complete and accurate

- Safety features function properly

The mold inspection and acceptance stage represents the final evaluation in the molding process, where the completed mold is thoroughly assessed to ensure it meets all design requirements, performance specifications, and quality standards. This stage provides the final validation that the entire molding process has been successful and the mold is ready for production use.

Mold acceptance is typically a collaborative process involving both the mold manufacturer and the customer, ensuring that all parties agree that the mold meets the established criteria for the intended molding process application.

Key Activities in Mold Inspection and Acceptance

Comprehensive Mold Inspection

A detailed examination of the mold structure, components, and finishes to verify compliance with design specifications. This includes checking:

- Overall dimensions and alignment of mold plates

- Condition and finish of cavity and core surfaces

- Proper functioning of all moving components

- Integrity of cooling and heating systems

- Correct installation of all standard components

- Proper marking and identification as required

Production Part Approval

Evaluation of parts produced during final testing to ensure they meet all dimensional, cosmetic, and functional requirements:

- Dimensional inspection against engineering drawings

- Visual inspection for surface defects and cosmetic quality

- Functional testing relevant to the part's intended use

- Material property verification through testing

- Statistical process control analysis of sample parts

- Validation of part consistency across multiple cycles

Performance Verification

Assessment of the mold's production capabilities and performance characteristics:

- Cycle time verification against requirements

- Production rate and stability over extended runs

- Ejection efficiency and part handling characteristics

- Material usage and waste generation

- Energy consumption during operation

- Operator safety and ease of maintenance

Documentation Review and Approval

Verification that all required documentation is complete, accurate, and delivered:

- As-built drawings and specifications

- Material certificates and热处理 records

- Test reports and inspection records

- Maintenance procedures and schedules

- Operating parameters and process sheets

- Spare parts list and recommended inventory

The acceptance process often involves a formal sign-off by the customer, acknowledging that the mold meets all agreed-upon requirements and is ready for production. This sign-off typically releases the final payment to the mold manufacturer and marks the official completion of the molding process.

In some cases, the acceptance process may include a trial production run where the mold produces parts under actual production conditions for an extended period. This validates the mold's durability and performance over time, ensuring it can meet the expected production volumes and maintain part quality throughout its service life in the molding process.

Once accepted, the mold is typically transferred to the production floor, where it begins its operational life. The completion of successful acceptance testing gives both the manufacturer and customer confidence that the mold will perform reliably in the production environment, delivering high-quality parts consistently as part of the ongoing molding process.

Types of Molds

The molding process encompasses a wide variety of mold types, each designed for specific materials, part geometries, and production requirements. While the fundamental principles of mold manufacturing apply across different types, each has unique characteristics that influence the specific implementation of the molding process.

Stamping Dies

Used for forming and shaping sheet metal through processes like blanking, punching, bending, and drawing. These molds are critical in the metal forming molding process for automotive, appliance, and aerospace components.

Plastic Molds

Designed for shaping plastic materials through processes like injection molding, blow molding, compression molding, and extrusion. These are among the most complex molds in the molding process due to intricate cooling systems.

Forging Dies

Used to shape metal through hot or cold forging processes, where metal is deformed under high pressure. These molds must withstand extreme forces in the molding process and are typically made from high-strength alloys.

Casting Molds

Used in processes like sand casting, die casting, and investment casting to form metal parts by pouring molten material into a cavity. The molding process varies significantly based on the casting method and material.

Powder Metallurgy Molds

Designed for compressing metal powders into solid parts through pressure and sintering. These molds in the molding process produce complex shapes with precise dimensional control and material properties.

Rubber Molds

Specialized for rubber and elastomer materials using processes like compression, injection, and transfer molding. The molding process for rubber requires careful temperature and pressure control to achieve proper curing.

Commonalities in the Molding Process Across Different Mold Types

While each mold type has unique characteristics, they share several fundamental aspects in their manufacturing process:

Design and Engineering Principles

All molds require careful design considering material flow, cooling/heating, part ejection, and dimensional accuracy, regardless of the specific molding process.

Material Selection Criteria

Mold materials are chosen based on factors like expected production volume, material being processed, required surface finish, and operating conditions in the molding process.

Precision Requirements

All molds require precise manufacturing to ensure dimensional accuracy of the final parts, with tolerance requirements varying based on application in the molding process.

Testing and Validation

Regardless of type, all molds undergo testing to verify performance, with adjustments made to optimize the molding process and part quality.

Maintenance Considerations

All molds require regular maintenance to ensure longevity and consistent performance, with specific procedures varying based on the molding process and materials involved.

Cost-Benefit Analysis

The design and manufacturing of all molds involve balancing initial cost with expected production volume, part complexity, and performance requirements in the molding process.

Conclusion

The mold manufacturing process is a complex, multi-stage endeavor that transforms design concepts into functional tools for production. From initial technical preparation through final inspection and acceptance, each stage of the molding process requires precision, expertise, and attention to detail to ensure the final mold meets all performance requirements.Optical Transceiver.

Advancements in technology, including CAD/CAM systems, CNC machining, and advanced materials, continue to enhance the precision, efficiency, and capabilities of the modern molding process. These innovations have reduced lead times, improved quality, and expanded the possibilities for complex part geometries across all mold types.Electronic shelf labels.

Understanding the complete mold manufacturing process is essential for anyone involved in product development, manufacturing engineering, or production management, as it forms the foundation for efficient, high-quality production of both plastic and metal components.Related lithium battery technology.

Learn more