Introduction to Mold Parts Manufacturing

The field of mold manufacturing involves a diverse range of components, each with unique functions, shapes, and performance requirements. Injection molding mold parts, in particular, represent a complex system of interconnected components working together to produce consistent, high-quality plastic parts.

While the variety of injection molding mold parts is extensive, they can be systematically categorized based on their structural and processing characteristics. This classification helps manufacturers develop efficient production strategies, select appropriate machining methods, and ensure consistent quality across all components.

Understanding these classifications is fundamental to mastering mold manufacturing processes, as each category of injection molding mold parts presents distinct challenges and requires specific machining approaches to achieve the required precision and performance.

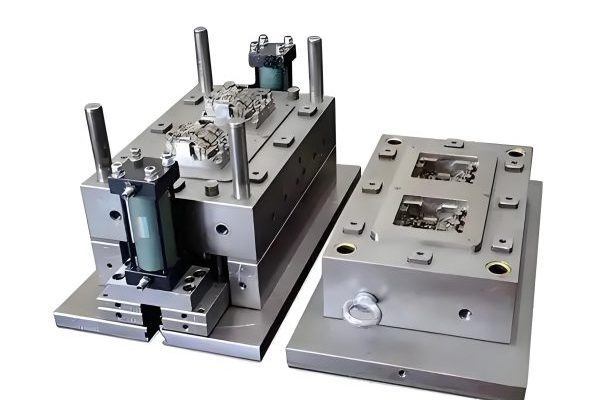

Complexity of Mold Assemblies

A typical mold assembly contains dozens of specialized injection molding mold parts, each requiring precise manufacturing to ensure proper fit and function.

- Diverse materials and finishes

- Varied dimensional tolerances

- Specialized performance requirements

Classification of Mold Parts

Although there are many parts that make up a mold structure, with different functions, shapes, and usage requirements, they can be roughly divided into the following four categories based on their structural processing characteristics. This classification system applies to most injection molding mold parts and helps standardize manufacturing processes.

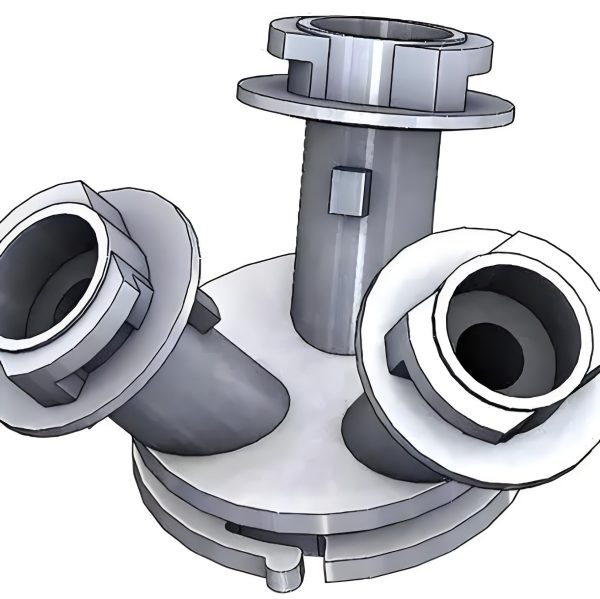

Shaft Sleeve Type Parts

This category of injection molding mold parts includes components designed with cylindrical or sleeve-like structures that facilitate movement, alignment, or guiding functions within the mold assembly.

Key examples of shaft sleeve type injection molding mold parts include:

- Guide pillars (leader pins) - ensure precise alignment between mold halves

- Guide bushings - provide low-friction surfaces for guide pillars

- Sprue bushings - create the entry point for molten plastic into the mold

- Mold handles - facilitate mold handling and mounting

- Locating rings - position the mold accurately in the injection machine

These injection molding mold parts typically require high precision in their cylindrical surfaces to ensure proper functioning and alignment within the mold assembly.

Rod Type Parts

Rod type injection molding mold parts consist of elongated, cylindrical components primarily responsible for actuation, ejection, or structural support within the mold system.

Common examples of rod type injection molding mold parts include:

- Ejector pins - push molded parts out of the cavity after forming

- Return pins - reset the ejection system after part removal

- Push rods - transmit force from the ejection system to ejector plates

- Sprue pullers - remove the sprue from the mold after injection

These injection molding mold parts require precise dimensional control to ensure proper alignment and function, often with specific hardness requirements to withstand repeated mechanical stress during mold operation.

Plate Type Parts

Plate type injection molding mold parts form the structural foundation of the mold, providing support, mounting surfaces, and containment for other components.

Typical plate type injection molding mold parts include:

- Mold plates - form the main structure containing cavities and cores

- Backing plates - provide support and distribute clamping forces

- Stripper plates - remove molded parts from cores or cavities

- Ejector plates - house and actuate ejection system components

- Spacers - maintain proper distance between mold plates

These injection molding mold parts often require flatness and parallelism controls, with precise hole patterns for alignment and mounting of other components.

Forming Parts

Forming injection molding mold parts directly shape the plastic material, determining the final geometry and surface finish of the molded product. These are often the most complex and critical components of the mold.

Key forming injection molding mold parts include:

- Punches (cores) - create internal features and cavities in the molded part

- Die cavities - form the external shape of the molded product

- Cores - create recessed areas or holes in the molded part

- Cavities - define the outer surface and contours of the molded product

These injection molding mold parts require the highest precision and surface quality, as they directly influence the appearance and dimensional accuracy of the final product.

Practical Example: Soap Box Injection Mold

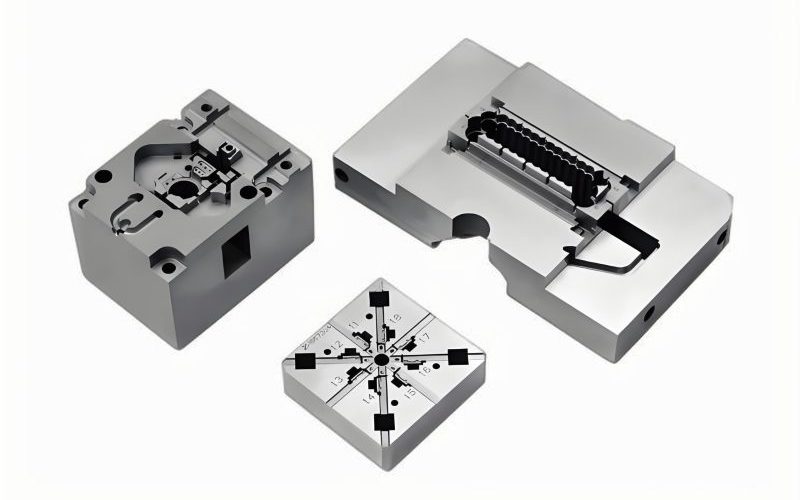

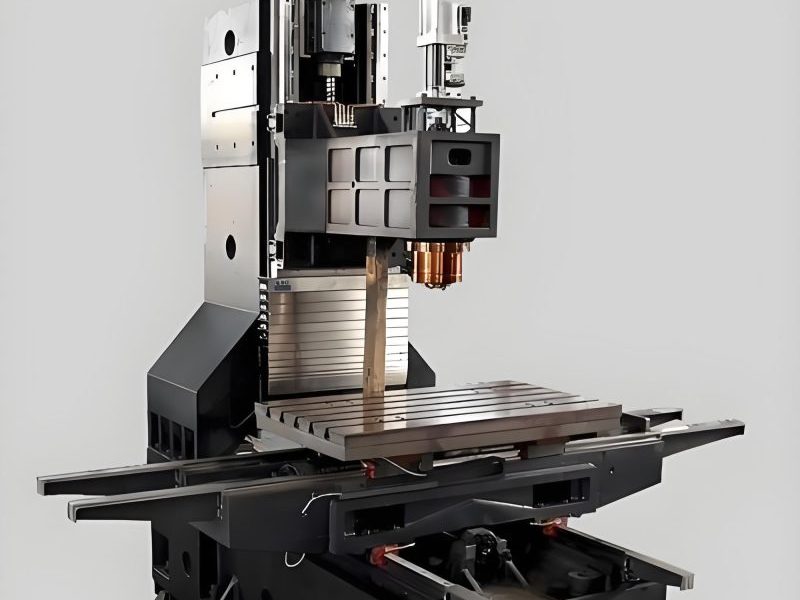

Figure 1-3: Classification of components in a typical soap box injection mold assembly

Taking a soap box injection mold as an example, the classification of its various components is shown in Figure 1-3. The manufacturing of this mold is typically carried out on the basis of purchasing a standard mold base, which contains many of the basic plate type and shaft sleeve type injection molding mold parts.

The standard mold base provides the foundational structure, including the main mold plates, guide pillars, and guide bushings. To this base, manufacturers add custom-formed injection molding mold parts such as the cavity and core that define the soap box shape, as well as the ejection system components like ejector pins and return pins.

This modular approach—combining standard injection molding mold parts with custom-formed components—balances cost efficiency with the need for precision, allowing manufacturers to produce high-quality molds while minimizing production time and costs.

Basic Surface Forms of Mold Parts

Although the shapes of injection molding mold parts vary, the basic surface configurations of each part can be summarized into the following three forms. Understanding these fundamental surface types is essential for determining appropriate machining methods for injection molding mold parts.

Rotational Surfaces

These include outer cylindrical surfaces, inner cylindrical surfaces, conical surfaces, and other rotational surfaces of rotational body parts. Common in shaft sleeve and rod type injection molding mold parts, these surfaces are generated by rotating a curve around a fixed axis.

Flat Surfaces

These include the surfaces of plate-type parts, the end faces of shafts, and other planar surfaces. Characterized by uniform elevation across the surface, these are predominant in plate type injection molding mold parts and require precise flatness control.

Curved Surfaces

These include contour curved surfaces and spatial curved surfaces of forming parts. The most complex surface type, these are critical in forming injection molding mold parts where they directly determine the final product's shape.

The Essence of Mold Part Processing

The processing of injection molding mold parts essentially involves solving the manufacturing challenges presented by these three basic surface types. Each surface form requires specific machining approaches to achieve the required dimensional accuracy, surface finish, and geometric characteristics.

For rotational surfaces and flat surfaces, conventional mechanical cutting processes are usually sufficient for forming. For those requiring high dimensional accuracy, CNC machining methods can be employed. The processing of curved surfaces, however, primarily relies on CNC milling (or machining centers), while for curved surfaces that are difficult to machine by mechanical methods, special processing techniques can be used.

Mold Part Processing Methods

Additionally, depending on the material of the part and to meet different surface precision requirements for injection molding mold parts, it is necessary to reasonably formulate processing technology plans based on specific requirements. The selection of appropriate manufacturing processes directly impacts the quality, cost, and production time of injection molding mold parts.

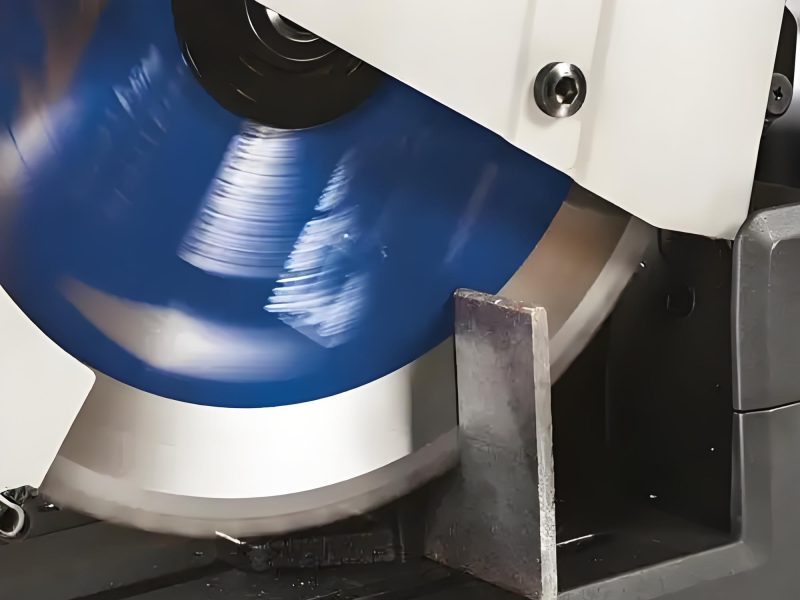

Conventional Mechanical Cutting

Conventional mechanical cutting generally uses universal machine tools to process injection molding mold parts. Initially, workers use ordinary milling machines, lathes, and other equipment for roughing and semi-finishing, followed by钳工 (fitter) work for correction, grinding, and polishing.

This process plan for injection molding mold parts has lower production efficiency, longer lead times, and quality that is difficult to guarantee consistently. The precision and consistency of machined parts rely heavily on the skill level of workers, making it challenging to achieve uniform quality across multiple mold sets.

However, this method requires less equipment investment and offers high machine versatility. It remains indispensable as a roughing and semi-finishing process before precision machining and electrical discharge machining (EDM) operations for injection molding mold parts.

Key Applications in Mold Manufacturing:

- Rough shaping of plate type injection molding mold parts

- Initial machining of shaft sleeve and rod type components

- Preparation for precision machining operations

- Cost-effective production of simple mold components

CNC Machine Tool Processing

CNC machining refers to the use of CNC milling machines, CNC lathes, machining centers, and other computer-controlled equipment for roughing, semi-finishing, and finishing of injection molding mold parts. High-precision forming grinders and coordinate grinders are used for finishing parts with high hardness after heat treatment.

This process reduces reliance on highly skilled workers and significantly improves production efficiency. For complex forming injection molding mold parts that would be difficult or impossible to machine accurately with universal machine tools, CNC machining offers an ideal solution.

The primary disadvantage compared to conventional mechanical processing is the higher initial investment in equipment. However, this is often offset by improved accuracy, reduced labor costs, and shorter production times for complex injection molding mold parts.

Advantages for Mold Manufacturing:

- Consistent precision across multiple injection molding mold parts

- Ability to produce complex geometries in forming components

- Reduced lead times through automated processing

- Capability to achieve tight tolerances in critical surfaces

Special Processing

Special processing mainly refers to forming methods such as electrical discharge machining (EDM), wire electrical discharge machining (WEDM), chemical etching, electrochemical machining, and electroforming. These techniques are particularly valuable for injection molding mold parts with complex geometries or hard materials that are difficult to machine using conventional methods.

For injection molding mold parts that are difficult or impossible to machine with conventional mechanical methods, special processing techniques are generally employed. These methods remove material through non-mechanical means, allowing for the production of extremely complex shapes and features that would be challenging or impossible with traditional cutting tools.

Electrical Discharge Machining (EDM)

Uses electrical sparks to erode material, ideal for hardenable steels and complex cavities in forming injection molding mold parts.

Wire EDM

Cuts complex shapes using a thin, electrically charged wire, perfect for intricate profiles in injection molding mold parts.

Chemical Etching

Uses chemical solutions to remove material, suitable for creating fine details and textures on injection molding mold parts.

Electroforming

Builds parts through electrolytic deposition, ideal for producing high-precision, complex forming injection molding mold parts.

Selecting the Right Processing Method

The selection of processing methods for injection molding mold parts depends on multiple factors, including part complexity, material, required precision, surface finish, production volume, and cost considerations. A strategic approach to process selection ensures that each category of injection molding mold parts receives the most appropriate manufacturing treatment.

| Part Category | Typical Surface Forms | Primary Processing Methods | Secondary Operations |

|---|---|---|---|

|

Shaft Sleeve Type

|

Rotational surfaces, cylindrical forms

|

|

|

|

Rod Type

|

Rotational surfaces, flat ends

|

|

|

|

Plate Type

|

Flat surfaces, hole patterns

|

|

|

|

Forming Parts

|

Complex curves, 3D surfaces

|

|

|

Cost vs. Performance Considerations

When selecting processing methods for injection molding mold parts, manufacturers must balance cost considerations with performance requirements. While CNC and special processing offer superior precision for complex injection molding mold parts, they may be unnecessarily expensive for simple components.

A hybrid approach—using conventional methods for simple features and advanced techniques for complex geometries—often provides the optimal solution for producing high-quality injection molding mold parts at a reasonable cost.

Process Sequencing for Optimal Results

The sequence of processing steps significantly impacts the quality and efficiency of producing injection molding mold parts. Typically, manufacturing progresses from roughing to semi-finishing to finishing operations, with heat treatment strategically placed to minimize distortion effects.

This structured approach ensures that each processing step builds upon the previous one, gradually refining the injection molding mold parts toward their final dimensions and surface characteristics.

The classification of injection molding mold parts into shaft sleeve, rod, plate, and forming categories provides a systematic framework for understanding mold structure and manufacturing requirements. By recognizing the three fundamental surface forms—rotational, flat, and curved—manufacturers can select appropriate processing methods to efficiently produce high-quality injection molding mold parts.

Whether using conventional mechanical cutting, CNC machining, or special processing techniques, the goal remains consistent: to produce injection molding mold parts that meet precise dimensional requirements, surface finish specifications, and performance criteria. The continued advancement of machining technologies will further enhance the precision, efficiency, and capabilities of mold manufacturing processes.