Functional Structure and Components of Stamping Dies

A comprehensive guide to the intricate design and components that form the backbone of modern stamping technology, focusing on the essential mold parts that enable precise manufacturing.

Introduction to Stamping Die Architecture

Stamping dies are precision tools used in manufacturing processes to shape and form metal sheets into desired configurations. These complex assemblies consist of various specialized components working in harmony to produce consistent, high-quality parts. The basic structure of a stamping die can be divided into two primary categories: process-related components and auxiliary components, each containing specific mold parts designed for particular functions.

Understanding the composition and functionality of these mold parts is crucial for anyone involved in die design, manufacturing, maintenance, or operation. Each component plays a vital role in the overall performance, accuracy, and longevity of the die. From the critical working elements that directly shape the material to the supporting structures that ensure stability and alignment, every piece contributes to the die's effectiveness.

This detailed overview explores each category of mold parts, their specific functions, and how they integrate within the complete die system. Whether you're an experienced engineer or new to the field, this guide provides valuable insights into the sophisticated world of stamping die components.

Fig. 1: A cross-sectional view of a typical stamping die showing various mold parts working together

Process-Related Components

Process-related components are the mold parts that directly participate in the material forming process. These critical elements come into contact with the workpiece and are responsible for shaping, cutting, or forming the material according to specifications. They are typically subjected to high levels of stress, wear, and fatigue, requiring them to be manufactured from high-quality materials with appropriate heat treatment to ensure durability and performance.

1. Working Components

The working components represent the most critical mold parts in any stamping die, as they directly shape and form the material. These components must maintain precise dimensions and sharp edges to ensure the quality of the finished parts. They are often made from high-carbon, high-chromium tool steels that can be heat-treated to achieve exceptional hardness and wear resistance.

Punches

Punches are male mold parts that exert force on the material, often working in conjunction with dies to cut or form shapes. They come in various configurations depending on the application, including flat punches, shaped punches, and piercing punches. The design of a punch must consider factors such as the material being processed, the desired shape, and the required precision.

Dies

Dies are female mold parts that work with punches to shape or cut material. They typically have cavities or openings that correspond to the desired shape of the finished part. Dies must be designed to withstand the extreme pressures involved in stamping operations while maintaining their dimensional accuracy over thousands of cycles.

Combination Punches and Dies

These specialized mold parts perform multiple functions in a single operation, such as cutting and forming simultaneously. They are particularly useful in complex stamping processes where space is limited or production speed is critical. Combination tools reduce the number of operations needed, increasing efficiency and reducing production time.

Cutting Inserts

Cutting inserts are replaceable mold parts that form the cutting edges of punches and dies. They are often made from carbide or other ultra-hard materials to extend tool life, especially when processing high-strength or abrasive materials. The use of inserts allows for easier maintenance and reduces the cost of replacing entire tools when edges become worn.

Fig. 2: Examples of working mold parts showing different punch and die configurations

2. Locating Components

Locating components are essential mold parts that ensure precise positioning of the workpiece within the die. Accurate location is critical for maintaining dimensional consistency, especially in progressive dies where the material moves through multiple stations. These components must provide reliable positioning while allowing for the slight variations that naturally occur in material dimensions and properties.

| Locating Component | Function | Typical Applications |

|---|---|---|

| Locating Pins | Precisely position the workpiece using pre-existing holes | Secondary operations, transfer dies |

| Stock Stops | Limit material advancement in the feed direction | Blanking dies, simple forming operations |

| Pilots | Align material using previously punched holes | Progressive dies, multi-stage operations |

| Guide Plates | Control lateral movement of strip material | Progressive dies, coil-fed operations |

| Pitch Limiters | Ensure consistent material advancement between stations | Progressive dies with precise spacing requirements |

The selection and placement of these mold parts depend on several factors, including material type, thickness, part complexity, and production volume. In high-speed production environments, locating components must operate with minimal friction to prevent material damage while maintaining accurate positioning. Many modern dies incorporate spring-loaded locating elements that can compensate for minor material variations while providing consistent positioning.

Fig. 3: Assortment of locating mold parts used in precision stamping operations

3. Stripping and Ejecting Components

After the forming or cutting operation, the workpiece often remains in contact with the punch or within the die cavity. Stripping and ejecting components are specialized mold parts designed to separate the finished part from the tooling, ensuring smooth operation and preventing damage to both the part and the die. These components must provide sufficient force to remove the part while operating smoothly and reliably through thousands of production cycles.

Pressure Plates

These mold parts apply pressure to the material during the stamping process, holding it securely in place while allowing the punch to penetrate. After the operation, they help strip the material from the punch. Pressure plates are often spring-loaded to provide consistent force throughout the stroke.

Stripper Plates

Stripper plates are essential mold parts that remove the material from the punch after the cutting or forming operation. They can be fixed or movable, with spring-loaded versions being common in applications where consistent stripping force is required.

Ejectors

Ejectors are mold parts designed to push finished parts out of die cavities. They come in various forms, including pins, plates, and sleeves, and are often actuated by springs, air pressure, or cam mechanisms depending on the application requirements.

Lift Pins

These specialized mold parts raise the material after each stamping operation, allowing for easier feeding to the next station. They are particularly useful in progressive dies where maintaining consistent material position between operations is critical.

Push Plates

Push plates are larger mold parts that provide uniform ejection force across the surface of a part. They are commonly used for larger components where multiple ejection points are needed to prevent part distortion during removal.

Stripper Bolts

These mold parts guide and limit the movement of stripper plates, ensuring proper alignment and preventing damage to other components. They often incorporate springs to provide the necessary stripping force while maintaining plate position.

The design of stripping and ejecting systems requires careful consideration of the part geometry, material properties, and production speed. Insufficient force can result in parts remaining in the die, causing jams and production delays, while excessive force can damage the part or the mold parts themselves. Many modern dies use adjustable systems that allow for fine-tuning of ejection forces based on specific production requirements.

Fig. 4: Cross-section showing stripping and ejecting mold parts in operation

Auxiliary Components

While auxiliary components may not directly participate in the material forming process, they are essential mold parts that ensure the proper functioning, alignment, and durability of the entire die assembly. These components provide support, guidance, and structural integrity, allowing the process-related components to perform their functions accurately and reliably. Without properly designed and manufactured auxiliary components, even the most precisely crafted working parts would fail to produce consistent, high-quality results.

4. Guiding Components

Guiding components are critical mold parts that ensure precise alignment between the upper and lower halves of the die during operation. Maintaining accurate alignment is essential for producing consistent parts, preventing damage to working components, and ensuring safe operation. These components must withstand the forces generated during stamping while maintaining their precision over thousands of cycles.

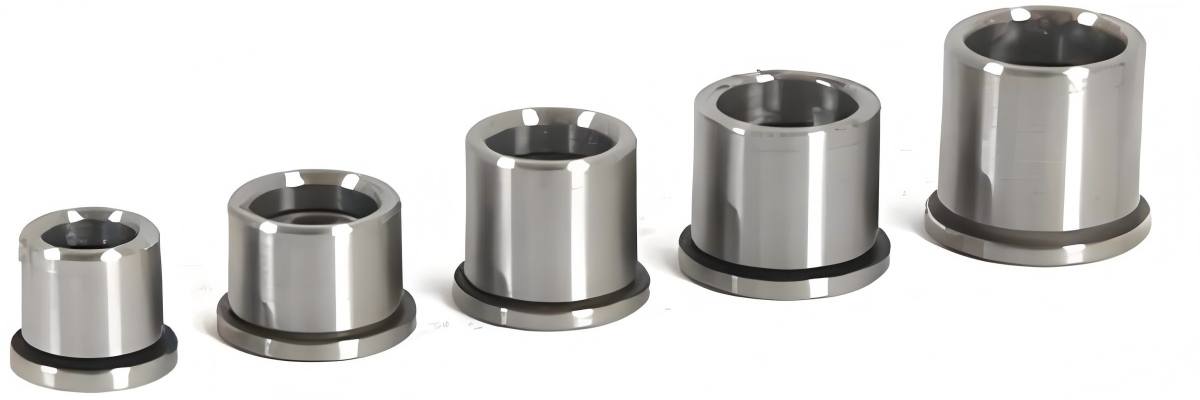

Guide Posts

Guide posts are cylindrical mold parts attached to one half of the die (usually the lower half) that slide within guide bushings or bearings in the other half. They come in various configurations, including straight, stepped, and shoulder designs, and are typically made from high-carbon steel that has been hardened and ground to precise dimensions. The surface finish of guide posts is critical, as it directly affects friction, wear, and overall die life.

Guide Bushings

Guide bushings are cylindrical mold parts that receive the guide posts, providing a low-friction surface for the sliding motion between die halves. They can be press-fit into the die plates or designed as replaceable components for easier maintenance. In high-performance applications, bushings may be made from self-lubricating materials or incorporate oil grooves to ensure proper lubrication during operation.

Guide Plates

Guide plates are flat mold parts that provide sliding surfaces between the upper and lower die assemblies. They are often used in conjunction with guide posts and bushings to provide additional stability and alignment. Guide plates are typically made from hardened steel with a precision ground surface to minimize friction and wear.

Gibs and Wear Plates

These specialized mold parts provide precise sliding surfaces for moving components within the die. Gibs are angled plates that allow for adjustment to maintain proper clearance, while wear plates provide replaceable surfaces in high-wear areas. Both types of components help maintain die precision over time and reduce maintenance requirements.

Fig. 5: Precision guide posts and bushings - essential guiding mold parts for die alignment

5. Supporting and Clamping Components

Supporting and clamping components form the structural framework of the die, providing stability and mounting surfaces for all other mold parts. These components must be rigid enough to withstand the forces generated during stamping without excessive deflection, which could affect part quality. They also serve as the interface between the die and the press, ensuring proper installation and alignment within the production equipment.

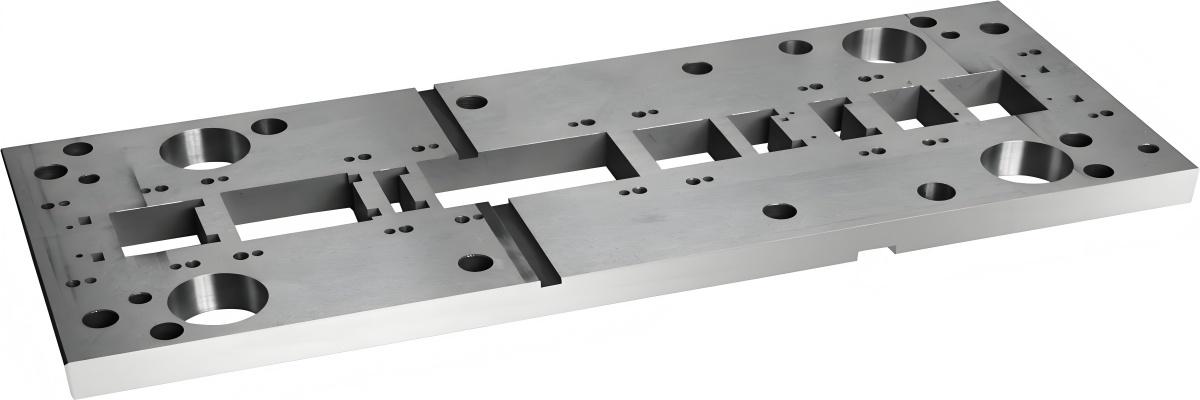

Upper and Lower Die Plates

These are the primary structural mold parts that form the base of the upper and lower die assemblies. They provide mounting surfaces for other components and distribute the stamping forces across the die. Die plates are typically made from medium-carbon steel and may be heat-treated for increased strength in high-force applications. Their thickness and material selection depend on the size of the die and the forces involved in the stamping process.

Die Handles

Die handles are mold parts that secure the upper die assembly to the press ram. They come in various styles, including straight, tapered, and flange types, to match different press configurations. The design of the die handle is critical for ensuring proper alignment between the die and the press, as well as for transmitting the stamping force efficiently.

Retention Plates

Retention plates are mold parts that secure working components such as punches and dies in their proper positions within the die assembly. They provide support during the stamping operation, preventing deflection of the working parts under load. Retention plates are often made from hardened steel and machined to precise dimensions to ensure accurate positioning of the components they hold.

Backing Plates

Backing plates are mold parts placed behind working components to distribute the stamping forces over a larger area, reducing stress concentrations in the die plates. They are particularly important for large punches or dies where the force per unit area would otherwise be too high. Backing plates are typically made from high-strength steel and may be heat-treated for additional hardness.

Limit Stops

These mold parts control the maximum closure of the die, preventing damage to components from excessive pressure or misalignment. They can be adjustable to fine-tune the die closure height, ensuring consistent part dimensions. Limit stops are often made from hardened steel to withstand repeated contact during die operation.

Spacer Blocks

Spacer blocks are mold parts used to create precise gaps between other components, establish working heights, or provide additional support where needed. They come in various sizes and configurations and can be made from steel, aluminum, or other materials depending on their specific application and load requirements.

Fig. 6: Structural mold parts including die plates, retention plates, and backing plates

6. Fastening Components and Other Parts

Fastening components are the unsung heroes of die construction, holding all other mold parts together in their precise positions. While often small in size compared to other components, they play a crucial role in maintaining the overall integrity and precision of the die. Additionally, various other specialized components contribute to the safe and efficient operation of the die.

Fastening Components

Socket Head Cap Screws

These high-strength fasteners are commonly used to secure mold parts due to their high clamping force and low profile head, which minimizes interference with other components.

Socket Set Screws

Used to secure rotating or sliding mold parts relative to each other, these screws exert pressure directly on the surface of the part being secured.

Dowel Pins

Precision-ground cylindrical mold parts that provide accurate alignment between components, working in conjunction with screws to prevent shifting under load.

Flat Washers

Used under screw heads and nuts to distribute clamping force, prevent damage to mold parts, and provide a smooth bearing surface.

Lock Washers

These specialized washers prevent screws from loosening due to vibration during die operation, ensuring that mold parts remain securely fastened.

Threaded Inserts

Used in softer materials to provide strong threaded connections for screws, preventing stripped threads in mold parts that require frequent disassembly.

Other Specialized Components

Springs

Springs are versatile mold parts used in various applications throughout the die, including providing force for stripper plates, ejectors, and locating components. They come in various types, including coil, leaf, and gas springs, each selected based on the force requirements and space constraints of the application.

Lifting Handles

These mold parts provide safe and convenient gripping points for moving and installing dies. They are designed to withstand the weight of the die and are often foldable or removable to prevent interference during operation.

Support Brackets

Support brackets are mold parts used to mount auxiliary equipment such as sensors, lubrication systems, or part detection devices. They can also provide additional structural support in areas of high stress.

Safety Components

These include various mold parts such as safety interlocks, guards, and sensors that ensure safe operation of the die. They prevent access to hazardous areas during operation and can stop the press if unsafe conditions are detected.

Fig. 7: Assortment of fastening mold parts used in die assembly and construction

Distribution of Mold Parts in Stamping Dies

The following chart illustrates the relative proportion of different categories of mold parts in a typical stamping die assembly. This distribution can vary depending on the complexity of the part being produced, the materials involved, and the specific stamping processes required.

Fig. 8: Relative proportion of different categories of mold parts in a typical stamping die

Summary of Mold Parts in Stamping Dies

Stamping dies are complex assemblies composed of numerous specialized mold parts working together to transform flat sheet metal into finished components. The careful selection and design of each component are essential to ensure the die produces high-quality parts consistently, operates efficiently, and maintains a long service life.

Process-related mold parts, including working components, locating components, and stripping/ejecting components, directly interact with the material to shape it into the desired form. These components must be manufactured to precise specifications from high-quality materials to withstand the harsh conditions of stamping operations.

Auxiliary mold parts, such as guiding components, supporting structures, and fasteners, provide the framework and functionality that allow the process-related components to perform their roles effectively. While they may not directly shape the material, these components are critical to the overall performance and longevity of the die.

Understanding the function and importance of each category of mold parts is essential for anyone involved in the design, manufacture, maintenance, or operation of stamping dies. By recognizing how these components work together, engineers and technicians can optimize die performance, reduce downtime, and improve the quality of stamped parts.