Fundamentals of Mold Manufacturing Technology

A comprehensive guide to the processes, techniques, and technologies that drive modern mold production, with special focus on precision engineering and plastic mold manufacturing.

Essential Knowledge for Modern Mold Makers

This comprehensive resource covers the complete spectrum of mold manufacturing technology, from initial design through final production, with detailed insights into specialized processes for creating high-quality plastic mold components and other precision tooling.

Comprehensive Processes

Detailed explanations of all major manufacturing processes from design to finishing, including specialized techniques for plastic mold production.

Component Expertise

In-depth analysis of mold components and their functions, with specific focus on how each part contributes to overall mold performance.

Advanced Technologies

Exploration of cutting-edge machining technologies that enable the production of complex, high-precision molds for diverse applications.

The Molding Process of Mold Manufacturing

The mold manufacturing process is a complex sequence of operations requiring precision, expertise, and advanced technology. For a typical plastic mold, this process involves several critical stages that transform a concept into a functional tool capable of producing thousands or even millions of identical parts.

1. Design and Engineering

The process begins with detailed design using CAD (Computer-Aided Design) software. Engineers analyze the part geometry, material properties, and production requirements to create a mold design that ensures proper flow, cooling, and ejection. For a plastic mold, this stage includes determining gate locations, runner systems, and cooling channel placement to optimize the injection molding process.

2. Material Selection

Choosing the appropriate mold material is crucial for durability and performance. Common materials include various grades of steel and aluminum, selected based on factors like production volume, part complexity, and the type of material being molded. For high-volume plastic mold applications, hardened tool steels such as H13 or S7 are typically preferred for their superior wear resistance and heat tolerance.

3. Rough Machining

The selected material is subjected to rough machining operations to remove large amounts of material and create the basic shape of the mold components. This stage establishes the general form that will be refined in subsequent operations. For plastic mold bases, this often involves milling to create the overall dimensions and preliminary cavity shapes.

4. Precision Machining

This stage involves more accurate machining processes to achieve the final dimensions and surface finish. Operations include milling, turning, and grinding to create the intricate details required by the mold design. For complex plastic mold cavities, CNC machining centers with multi-axis capabilities are employed to produce the precise contours and features.

5. Heat Treatment

Many mold components undergo heat treatment to enhance hardness, toughness, and wear resistance. This is particularly important for plastic mold components that will be subjected to repeated cycles of heating and cooling during injection molding. Processes such as quenching and tempering are used to achieve the desired material properties.

6. Finishing Operations

Final polishing, texturing, or coating processes are applied to achieve the desired surface characteristics. For a plastic mold, surface finish directly affects the appearance of the molded part, with high-gloss finishes requiring mirror-like mold surfaces achieved through progressive polishing steps.

7. Assembly and Testing

Individual mold components are carefully assembled, and the complete mold undergoes rigorous testing. This includes trial runs to verify dimensional accuracy, cooling efficiency, and overall performance before production use. For plastic mold testing, actual production materials are often used to simulate real-world conditions.

Each stage of the mold manufacturing process requires specialized equipment and skilled technicians to ensure the final product meets the exacting standards required for efficient production. The complexity of the process underscores why experienced manufacturers are essential for producing high-quality molds, especially precision plastic mold solutions that must maintain dimensional stability over thousands of cycles.

Classification of Mold Components

A mold consists of numerous specialized components working together to produce consistent, high-quality parts. Each component has a specific function, and understanding their roles is essential for effective mold design and manufacturing. In a injection mold, these components must withstand repeated cycles of heating, cooling, and pressure while maintaining precise dimensional accuracy.

Structural Components

Provide framework and support for the entire mold assembly

Functional Components

Perform specific operations during the molding process

Structural Components

1. Mold Base

The foundation of the mold, providing structural support for all other components. It typically includes top and bottom plates, support pillars, and guide posts. In a plastic mold, the mold base must be rigid enough to withstand clamping forces during injection, which can range from several tons to hundreds of tons depending on mold size.

2. Guide Components

Include guide posts and bushings that ensure precise alignment between moving mold halves during operation. These components prevent damage to critical surfaces and ensure consistent part dimensions. In plastic mold applications, guide components must maintain their precision despite thermal expansion and contraction during repeated cycles.

3. Support Plates

Provide additional structural support for cavity and core inserts, especially in large molds or those with complex geometries. They distribute clamping forces evenly across the mold, preventing deflection that could affect part quality. This is particularly important in large plastic mold applications where uneven force distribution can cause dimensional variations in molded parts.

Functional Components

1. Cavity and Core Inserts

The most critical components that form the actual shape of the molded part. The cavity is the female portion, while the core is the male portion. In a plastic mold, these inserts are often made from high-grade tool steel to withstand thousands of cycles, with surface finishes that directly influence the appearance of the final plastic part.

2. Gating System

Includes sprue, runners, and gates that control the flow of material into the mold cavity. The design of this system significantly affects part quality, especially in a plastic mold where proper flow is essential to fill complex geometries without introducing defects like weld lines or air traps.

3. Cooling System

Consists of channels drilled or machined into mold plates to circulate cooling fluid. Efficient cooling is critical for cycle time reduction and part quality, making this system vital in plastic mold applications where cooling time can constitute up to 80% of the total cycle time.

4. Ejection System

Includes ejector pins, plates, and returns that remove the finished part from the mold after cooling. The design must carefully balance effective part removal with minimal part marking. In plastic mold design, ejection systems are often customized to match part geometry and prevent deformation of delicate features.

5. Venting Components

Small channels or gaps that allow air to escape from the mold cavity during material injection. Proper venting prevents burns, incomplete filling, and other defects in the finished part. In plastic mold applications, vents are typically 0.025-0.05mm deep to allow air escape while preventing plastic from flowing out.

6. Secondary Components

May include slides, lifters, and cores for producing undercuts or complex geometries. These components add complexity to the mold but enable the production of more intricate parts in a plastic mold. They often involve cam mechanisms or hydraulic/pneumatic actuators to move components during the molding cycle.

Each component in a mold must be manufactured to precise specifications and carefully assembled to ensure proper functionality. The quality of these components directly impacts the performance of the mold, the quality of the molded parts, and the overall production efficiency. This is especially true for high-precision applications where a plastic mold must maintain dimensional accuracy over thousands or even millions of production cycles in demanding industrial environments.

Applications of Turning in Mold Manufacturing

Mold Making.Turning is a machining process that involves rotating a workpiece while a cutting tool removes material to create cylindrical shapes. This versatile process plays a crucial role in mold manufacturing, particularly for producing rotational components used in various mold types, including the plastic mold industry where precision cylindrical parts are essential for proper mold function.

Key Turning Processes in Mold Making

- External turning for creating outer diameters and cylindrical surfaces

- Internal turning (boring) for producing holes and internal features

- Face turning for creating flat surfaces on the ends of workpieces

- Thread turning for producing internal or external threads

- Grooving and parting for creating slots, grooves, and separating workpieces

- Taper turning for creating conical surfaces

- Form turning for producing complex rotational profiles in a single operation

In mold manufacturing, turning is typically performed on lathes, which can range from manual machines for simple parts to sophisticated CNC (Computer Numerical Control) lathes for complex components requiring high precision. CNC turning centers offer enhanced capabilities, including multiple axes, live tooling, and automatic bar feeders, making them ideal for producing complex rotational components for plastic mold applications with consistent accuracy.

Common Mold Components Produced by Turning

Ejector Pins

Precision cylindrical pins used to eject molded parts from the mold cavity. Turning produces the precise diameters and surface finishes required for smooth operation without binding, which is critical for preventing damage to delicate plastic mold components.

Guide Posts and Bushings

Critical alignment components that require precise cylindrical surfaces and tight tolerances to ensure proper mold registration during operation. Turning achieves the dimensional accuracy needed for these components to function correctly over millions of cycles.

Sprue Bushings

Components that guide molten material into the mold. Turning creates the conical and cylindrical surfaces essential for proper material flow in a plastic mold, ensuring smooth transition of molten plastic from the injection nozzle to the runner system.

Threaded Inserts

Mold components with internal or external threads for assembly purposes. Thread turning produces precise threads that ensure proper fit and function, allowing for disassembly and maintenance of mold components when needed.

Locator Pins

Small diameter pins used to precisely position mold components relative to each other during assembly. Turning achieves the tight tolerances required for these components to ensure proper alignment of critical mold features.

Cooling Channel Fittings

Components that connect cooling lines to the mold. Turning creates the precise surfaces and threads needed for leak-free connections, which is essential for maintaining proper temperature control in plastic mold applications.

Advantages of Turning in Mold Manufacturing

- High precision and dimensional accuracy, often achieving tolerances of ±0.001mm or better

- Excellent surface finishes, reducing the need for additional polishing operations

- Efficiency in producing cylindrical components compared to other machining processes

- Capability to work with a wide range of mold materials, including hardened steels

- CNC turning enables complex geometries and consistent production of multiple identical parts

- Cost-effectiveness for both small and large production runs of rotational components

- Ability to produce both external and internal features in a single setup

Modern turning technology, particularly CNC turning, has significantly enhanced the capabilities of mold manufacturers. With advanced programming and tooling, CNC lathes can produce complex rotational components with features that would be difficult or impossible to achieve with manual methods. This is especially valuable in the production of plastic mold components, where precision and consistency directly impact the quality of the final molded parts and the overall efficiency of the production process.

The integration of turning with other machining processes creates a comprehensive manufacturing solution for mold components. While turning excels at cylindrical features, it is often combined with milling, grinding, and other processes to create complete mold components with both rotational and non-rotational features. This versatility makes turning an indispensable process in modern mold manufacturing facilities producing high-quality plastic mold solutions and other precision tooling.

Applications of Milling in Mold Manufacturing

Milling is a versatile machining process that uses rotating cutting tools to remove material from a workpiece. This process is fundamental to mold manufacturing, enabling the creation of complex shapes, flat surfaces, slots, and contours that form the cavities and cores of molds. In plastic mold production, milling plays a critical role in creating the precise geometries that define the final part's shape—ensuring that every detail is accurately reproduced in the molded plastic component, a core output of plastic molding.

Types of Milling Processes Used in Mold Making

- Face milling for creating flat surfaces on mold plates and inserts

- Peripheral milling for producing vertical or angled surfaces

- End milling for creating slots, pockets, and contours

- Ball nose milling for generating 3D curved surfaces and complex contours

- High-speed milling for achieving fine surface finishes and complex geometries

- Thread milling for producing internal and external threads

- Contour milling for creating complex profiles and shapes

- Roughing and finishing operations for efficient material removal

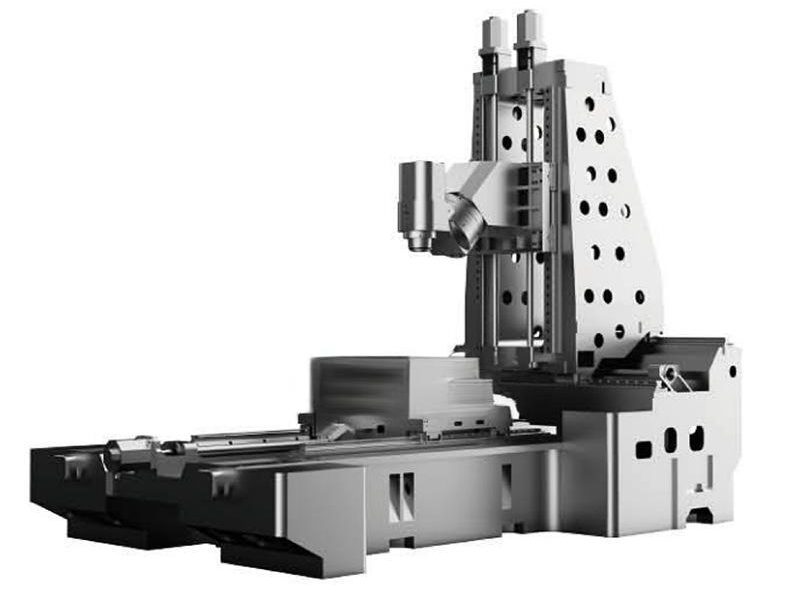

Mold manufacturing primarily utilizes CNC milling machines, which offer superior precision, repeatability, and flexibility compared to manual machines. These range from 3-axis machines for simple parts to 5-axis machines capable of producing highly complex geometries without repositioning the workpiece. The advanced capabilities of modern CNC milling centers make them indispensable for producing the intricate shapes required in plastic mold components, where even minor deviations can affect part quality or functionality.

Milling Applications in Mold Components

Cavity and Core Inserts

Milling creates the complex 3D surfaces and details of cavity and core inserts that directly form the molded part. High-speed ball nose milling is particularly effective for creating the smooth surfaces required in plastic mold components, allowing for precise replication of intricate part details.

Mold Plates

Face milling produces flat, parallel surfaces on mold base plates, while peripheral milling creates edges and shoulders for component alignment and assembly. Precision milling ensures that these foundational components provide accurate reference surfaces for subsequent operations.

Runner Systems

Milling cuts the channels that deliver molten material from the sprue to the mold cavities. Precise control of depth and width ensures proper material flow, pressure distribution, and filling characteristics in plastic mold applications.

Cooling Channels

While some cooling channels are drilled, complex cooling circuits often require 3D milling to create conformal cooling paths that follow the contour of the mold cavity. This advanced approach significantly improves cooling efficiency in plastic mold designs, reducing cycle times and improving part quality.

Ejection System Components

Milling produces the slots, pockets, and mounting surfaces for ejector pins, plates, and other ejection components. Precision milling ensures proper alignment and movement of these critical components during the ejection phase of the molding cycle.

Slide and Lifter Mechanisms

Complex milling operations create the guideways, cam surfaces, and mounting features for slides and lifters used in undercut molding applications. These components require precise milling to ensure smooth operation and proper part release in complex plastic mold designs.

Advancements in Milling Technology for Mold Making

High-Speed Milling (HSM)

HSM has revolutionized mold manufacturing by enabling faster material removal rates and superior surface finishes. This technology uses high spindle speeds (15,000-40,000 RPM) and specialized cutting tools to machine complex 3D surfaces with exceptional precision. For plastic mold production, HSM often eliminates the need for manual polishing, reducing lead times and improving consistency across multiple mold cavities.

5-Axis Milling

5-axis milling machines provide simultaneous movement of the workpiece or cutting tool along five axes, allowing complex geometries to be machined in a single setup. This capability is particularly valuable for producing deep cavities, undercuts, and complex curved surfaces common in modern plastic mold designs. 5-axis machining reduces setup time, improves accuracy, and enables the production of features that would be impossible with 3-axis machines.

The choice of milling tools is critical to achieving optimal results in mold manufacturing. Carbide and ceramic cutting tools are commonly used for their durability and ability to maintain sharp cutting edges during high-speed machining of hardened steels. Coatings such as TiAlN (titanium aluminum nitride) further enhance tool life and performance when machining the tough materials used in plastic mold components, allowing for higher cutting speeds and longer tool life.

Milling is often the most time-consuming process in mold manufacturing due to the complexity of mold geometries. To optimize efficiency, mold makers employ advanced CAM (Computer-Aided Manufacturing) software to generate efficient toolpaths that minimize machining time while maintaining precision. These software solutions simulate the machining process to identify potential collisions and optimize cutting strategies for complex 3D surfaces, ensuring that even the most intricate plastic mold components can be produced efficiently and accurately.

Applications of Grinding in Mold Manufacturing

Grinding is a precision machining process that uses an abrasive wheel to remove material from a workpiece, producing very fine surface finishes and tight tolerances. In mold manufacturing, grinding plays a critical role in achieving the dimensional accuracy and surface quality required for high-performance molds, including plastic mold components. These components demand exceptional surface finish to replicate onto the injection molded plastic (the final product of the mold), ensuring both functionality and aesthetic appeal of the plastic parts.

Types of Grinding Processes in Mold Making

- Surface grinding for achieving flat, parallel surfaces with high precision

- Cylindrical grinding for precision machining of cylindrical components

- Internal grinding for creating precise internal diameters and bores

- Centerless grinding for high-volume production of small cylindrical parts

- Tool and cutter grinding for manufacturing and reconditioning cutting tools

- Jig grinding for precise hole locations and complex contours

- Creep feed grinding for efficiently removing large amounts of material

- Spark-out grinding for achieving ultra-fine surface finishes

Grinding differs from other machining processes in that it removes material in very small increments, typically measured in microns. This allows for exceptional dimensional control, often achieving tolerances as tight as ±0.0001mm. For plastic mold components, this level of precision ensures proper fit between mating parts and contributes to the overall quality of the molded products, where even minor surface imperfections can be transferred to the plastic part.

Grinding Applications in Mold Components

Mold Plates

Surface grinding ensures mold base plates are perfectly flat and parallel, providing a stable foundation for other components. This is critical for preventing part defects in plastic mold applications where uneven clamping pressure can cause part warpage or dimensional variation.

Cavity and Core Inserts

Precision grinding achieves the final dimensions and surface finishes of cavity and core inserts. For high-gloss plastic mold applications, specialized grinding processes can produce mirror-like finishes that are directly transferred to the molded plastic parts, eliminating the need for secondary finishing operations.

Guide Components

Cylindrical and internal grinding create the precise diameters and surface finishes required for guide posts and bushings, ensuring smooth mold operation with minimal wear. This precision is essential for maintaining consistent part quality over the mold's lifetime.

Ejector Pins

Grinding produces the precise diameters and straightness required for ejector pins to function properly without binding or causing damage to molded parts. In plastic mold applications, this ensures consistent part ejection and minimizes cosmetic defects caused by misaligned ejector pins.

Slide and Lifter Surfaces

Precision grinding creates the smooth, flat surfaces required for slides and lifters to move with minimal friction and wear. This is particularly important in complex plastic mold designs where these moving components must operate reliably over thousands of cycles.

Critical Datum Surfaces

Grinding establishes precise reference surfaces used for measuring and aligning other components during mold assembly. These datum features ensure that all mold components work together harmoniously, which is essential for producing consistent parts in plastic mold applications.

Grinding Technology and Advantages

Precision and Accuracy

Grinding achieves dimensional tolerances and surface finishes that are difficult or impossible to obtain with other machining processes. This level of precision is essential for ensuring proper mold function and part quality, particularly in high-precision plastic mold applications where even minor imperfections can be transferred to the molded parts, affecting both appearance and functionality.

Capability with Hard Materials

Unlike many machining processes, grinding is effective for working with hardened materials. This allows mold components to be heat treated to improve hardness and wear resistance before final grinding, ensuring optimal performance in production. This is particularly valuable for plastic mold components that must withstand repeated cycles of heating and cooling, as well as the abrasive action of flowing plastic materials.

Surface Finish Control

Grinding offers exceptional control over surface finish, from rough finishes to mirror-like polished surfaces. In plastic mold manufacturing, the surface finish of cavity and core inserts directly affects the appearance of molded parts, making this capability crucial for producing high-quality plastic components that meet strict aesthetic requirements.

Modern grinding machines incorporate advanced technologies such as CNC controls, automatic wheel dressing, and in-process measurement systems to ensure consistent, high-precision results. These machines can be programmed to produce complex geometries with minimal operator intervention, improving efficiency and reducing variability. For plastic mold manufacturers, these advancements have translated into higher quality molds, shorter lead times, and greater ability to meet the demanding requirements of modern plastic parts.

Applications of CNC Machining in Mold Manufacturing

Computer Numerical Control (CNC) machining has revolutionized mold manufacturing for injection molding manufacturers (companies that rely on high-precision molds to support large-scale injection production), enabling precise, automated, and repeatable production of complex components. CNC technology integrates computer control with machining processes to produce parts with exceptional accuracy and consistency—critical for injection molding manufacturers tasked with creating modern plastic molds. In this manufacturing process, CNC machining is indispensable: it crafts the intricate geometries and tight tolerances required for high-quality molds that can produce consistent parts over thousands or millions of cycles, ensuring injection molding manufacturers meet the strict quality standards of downstream industries (e.g., automotive, electronics).

Types of CNC Machines Used in Mold Making

- CNC milling machines (3-axis, 4-axis, and 5-axis) for complex 3D shapes

- CNC turning centers for cylindrical components and rotational features

- CNC grinding machines for precision finishing operations

- CNC EDM (Electrical Discharge Machining) for complex shapes in hard materials

- CNC wire-cut EDM for precise contour cutting and intricate shapes

- CNC engraving machines for adding text, logos, and fine details

- Multi-tasking CNC machines that combine turning and milling capabilities

The heart of CNC machining is the computer control system that interprets CAD (Computer-Aided Design) models and generates toolpaths through CAM (Computer-Aided Manufacturing) software. This integration allows for seamless translation of design intent into physical components with minimal human intervention. For plastic mold manufacturing, this means complex part geometries can be reproduced accurately across multiple mold cavities and even across multiple mold builds, ensuring consistent part quality regardless of production volume.

Key Advantages of CNC Machining in Mold Manufacturing

Superior Precision

CNC machines achieve tolerances as tight as ±0.0001mm, ensuring mold components fit together perfectly and produce consistent parts. This level of precision is essential for high-quality plastic mold production where even minor variations can affect part functionality or assembly.

Repeatability

CNC machining produces identical components across multiple production runs, ensuring consistency between molds and reducing variation in molded parts. This is particularly valuable for plastic mold manufacturers producing multiple molds for the same part or maintaining mold libraries for future production runs.

Complex Geometry Capability

Multi-axis CNC machines can produce intricate shapes and contours that would be impossible or impractical to create with manual machining methods. This capability enables the production of complex plastic mold components that accurately replicate the detailed features of modern plastic parts.

Efficiency

CNC machines can operate unattended for extended periods, increasing productivity and reducing lead times for mold production. Advanced CNC systems with pallet changers and automated tool changers can produce complete plastic mold components with minimal operator intervention.

Design Flexibility

Changes to mold designs can be implemented quickly through CAD/CAM software, allowing for rapid prototyping and design iterations. This flexibility is crucial for plastic mold manufacturers responding to evolving part designs or engineering changes.

Material Versatility

CNC machines can process a wide range of mold materials, from aluminum to hardened tool steels, with consistent results. This versatility allows manufacturers to select the optimal material for each plastic mold application based on production volume, part complexity, and material requirements.

Advanced CNC Technologies in Mold Making

5-Axis CNC Machining

5-axis CNC machines provide simultaneous movement of the cutting tool along five axes, enabling complex 3D shapes to be machined in a single setup. This technology eliminates the need for multiple setups, reducing production time and improving accuracy. For plastic mold components with deep cavities or complex contours, 5-axis machining offers significant advantages over traditional 3-axis methods, allowing for better tool access and improved surface finishes.

High-Speed Machining (HSM)

High-speed CNC machining uses spindle speeds typically ranging from 15,000 to 40,000 RPM combined with high feed rates to remove material efficiently while producing fine surface finishes. HSM is particularly valuable for plastic mold manufacturing as it can produce polished surfaces that require little or no manual finishing, reducing production time and improving consistency across multiple mold cavities.

Adaptive Machining

Advanced CNC systems incorporate adaptive machining capabilities that adjust cutting parameters in real-time based on feedback from sensors. This technology optimizes material removal rates, extends tool life, and improves surface quality. In mold manufacturing, adaptive machining is particularly useful for processing difficult-to-machine materials commonly used in high-performance plastic mold applications, ensuring consistent results even with material variations.

The adoption of CNC technology has transformed mold manufacturing, enabling the production of more complex, higher quality molds with shorter lead times. For plastic mold manufacturers, CNC machining has become a cornerstone technology that supports the production of intricate, high-precision molds capable of meeting the demanding requirements of modern plastic parts. As CNC technology continues to advance, with improvements in speed, accuracy, and software capabilities, it will undoubtedly play an even more significant role in the future of mold manufacturing.

Applications of Special Processing in Mold Manufacturing

Special processing, also known as non-traditional machining, refers to a group of manufacturing processes that remove material using methods other than conventional cutting tools. These processes are essential for producing complex shapes in hard materials that would be difficult or impossible to machine with traditional methods— a necessity for mold injection manufacturer tasked with producing high-precision plastic mold components. In mold manufacturing, these special processing techniques play a crucial role for injection mold manufacturers in creating intricate features in hardened tool steels, as conventional machining would be impractical or ineffective for such components.

Common Special Processing Techniques in Mold Making

- Electrical Discharge Machining (EDM) - Sinker and wire-cut varieties

- Electrochemical Machining (ECM) for complex shapes in hard materials

- Electrochemical Grinding (ECG) for precision finishing

- Ultrasonic Machining for brittle materials

- Laser beam machining for fine cutting and surface texturing

- Water jet cutting for material preparation and rough shaping

- Plasma arc machining for cutting thick materials

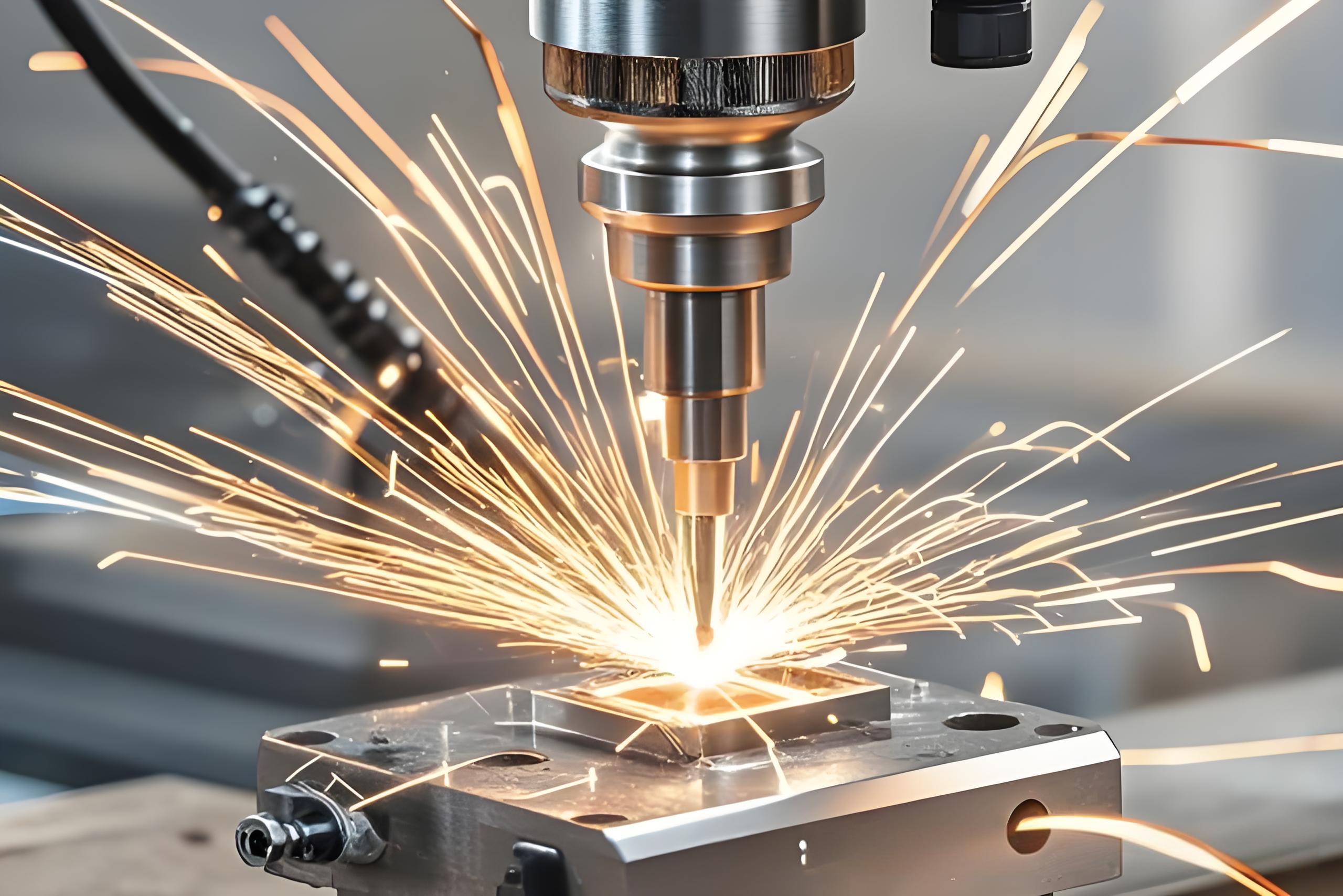

Among these special processes, Electrical Discharge Machining (EDM) is by far the most widely used in mold manufacturing. EDM works by using controlled electrical discharges (sparks) to erode material from the workpiece. This process is particularly valuable for machining hardened materials and creating complex shapes with tight tolerances, making it indispensable for plastic mold production where intricate details and high precision are required in materials that have been heat treated to enhance durability.

Electrical Discharge Machining (EDM) in Mold Manufacturing

Sinker EDM

Also known as die-sinking EDM, this process uses a shaped electrode to create a corresponding cavity in the workpiece. Sinker EDM is ideal for producing complex 3D shapes, deep cavities, and intricate details in plastic mold components that would be difficult or impossible to produce with conventional machining methods.

Wire EDM

This process uses a thin, continuously fed wire as an electrode to cut complex contours and shapes. Wire EDM is particularly useful for producing precision punches, dies, and intricate components with tight tolerances. In plastic mold manufacturing, wire EDM is often used to create complex cavity inserts and core details with high accuracy.

EDM offers several advantages for mold manufacturing. It can machine materials regardless of their hardness, allowing mold components to be heat treated before machining to improve wear resistance without sacrificing machinability. This is especially beneficial for plastic mold components that must withstand thousands of production cycles. EDM also produces no cutting forces, eliminating the risk of workpiece deformation and enabling the production of delicate features that would be damaged by traditional machining processes.

Applications of Special Processing in Mold Components

Complex Cavities and Cores

Sinker EDM is commonly used to create complex cavity and core inserts with intricate details, undercuts, and deep recesses that would be challenging to produce with conventional milling. For plastic mold applications with complex part geometries, EDM provides the precision and flexibility needed to replicate fine details accurately, ensuring that even the most intricate features are reproduced consistently in every molded part.

Precision Holes and Slots

EDM can produce small, precise holes and slots with high aspect ratios (depth-to-diameter) that are difficult to achieve with drilling or milling. This capability is essential for creating cooling channels, ejector pin holes, and venting in mold components. In plastic mold design, these features are critical for ensuring proper cooling, part ejection, and air evacuation during the molding process.

Surface Texturing

Laser machining and EDM texturing processes can create precise surface patterns and textures on plastic mold cavities. These textures are transferred to the molded plastic parts, creating desired aesthetic or functional surface finishes. From leather grains to custom patterns, these texturing processes provide mold makers with precise control over the visual and tactile properties of molded parts.

Micro-Machining

Special processes like micro-EDM and laser machining enable the production of extremely small features with micron-level precision. This capability is essential for micro-molding applications where plastic mold components must produce tiny, detailed parts for medical devices, electronics, and other precision applications. These processes can create features smaller than 0.1mm with exceptional accuracy.

Advantages and Limitations of Special Processing

Special processing techniques offer unique advantages for mold manufacturing, including the ability to machine hard materials, create complex shapes, and produce fine details with high precision. These processes are particularly valuable for plastic mold production where intricate details and surface finishes directly impact the quality of the molded parts and where traditional machining would be impractical or impossible.

However, special processing also has limitations. These processes typically remove material more slowly than conventional machining methods, making them more expensive for large volume material removal. They also require specialized equipment and expertise, increasing the complexity of the manufacturing process. As a result, special processing is usually reserved for features that cannot be produced economically with conventional methods, with most plastic mold components utilizing a combination of traditional and special processes to optimize both quality and cost.

In modern mold manufacturing, special processing techniques are often used in combination with conventional machining to optimize production. Roughing operations are typically performed with CNC milling to remove most of the material efficiently, while special processes are used for finishing operations, complex features, and hard materials. This hybrid approach balances efficiency and capability, resulting in high-quality molds at competitive prices. For plastic mold manufacturers, mastering these specialized processes is essential for staying competitive in an industry that increasingly demands more complex, higher quality parts with shorter lead times.

Advanced Mold Manufacturing Technologies

Modern mold manufacturing relies on a combination of advanced technologies to produce high-precision tools capable of meeting the demanding requirements of today's manufacturing environment, including specialized solutions for plastic mold applications.

5-Axis Machining

Produce complex geometries with exceptional precision in a single setup, ideal for intricate plastic mold components.

High-Speed Milling

Achieve mirror-like finishes on plastic mold components with minimal polishing requirements.

Precision EDM

Create intricate details and complex shapes in hardened materials for high-performance molds.

Advanced Metrology

Ensure dimensional accuracy with micron-level measurement capabilities critical for plastic mold quality control.