Mold Manufacturing Technology

The comprehensive guide to the most advanced and mature mold manufacturing techniques, processes, and management strategies in the industry.

Mold manufacturing is a critical process in modern industry, enabling the mass production of high-precision components. It involves the design and fabrication of tools that shape materials into specific forms. This section provides an in-depth understanding of the fundamental principles, key concepts, and industry standards in mold manufacturing.

Core Concepts

- Understanding the role of molds in manufacturing processes

- Differentiating between various mold types (injection, extrusion, die-casting, etc.)

- Key terminology and definitions in the mold manufacturing industry

- Overview of the mold manufacturing workflow

Modern mold manufacturing relies on advanced technologies such as CAD/CAM systems, precision machining, and materials science. These technologies enable the production of complex geometries with tight tolerances, meeting the demanding requirements of industries like automotive, aerospace, and consumer electronics.

Mold Types

Explore the different types of molds and their applications in various industries.

Industry Standards

Understanding global standards and certifications in mold manufacturing.

The development of a comprehensive process plan is crucial for ensuring the efficient and cost-effective production of high-quality mold components. This section delves into the methodologies and best practices for process planning in mold manufacturing, including material selection, machining operations, and quality control strategies.

Process Planning Steps

Component Analysis

Detailed examination of the mold component requirements and specifications.

Material Selection

Choosing the appropriate materials based on component function, durability, and cost.

Operation Sequencing

Determining the optimal sequence of machining operations to achieve required tolerances.

Tool Selection

Selecting the appropriate cutting tools and machining parameters.

Effective process planning requires a deep understanding of both the component design and the capabilities of available manufacturing equipment. Advanced software tools, such as computer-aided manufacturing (CAM) systems, play a vital role in optimizing process plans and reducing production lead times.

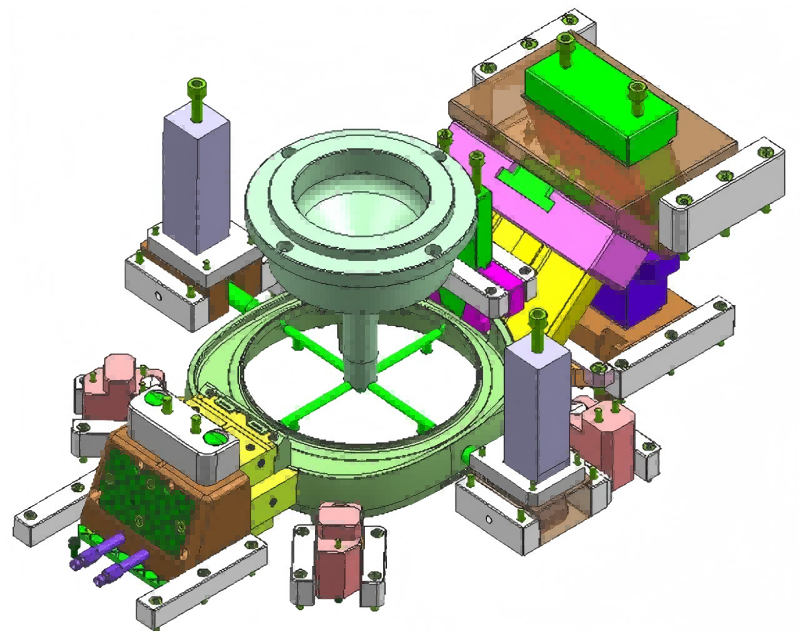

CAD/CAM Integration

How CAD/CAM systems streamline the process planning workflow.

Cost Estimation

Techniques for accurate cost estimation in mold manufacturing.

Conventional machining processes remain fundamental to mold manufacturing, providing cost-effective solutions for many mold components. This section explores the various conventional machining techniques used in mold production, including turning, milling, drilling, and grinding.

Turning Operations

Producing rotational components with high precision using lathes and turning centers.

Milling Processes

Creating complex shapes and features using various milling cutters and strategies.

Drilling Techniques

Precision hole making in mold components with various drill types and parameters.

Grinding Operations

Achieving tight tolerances and surface finishes through precision grinding processes.

While conventional machining methods are often perceived as outdated, advancements in tool materials, machine controls, and process optimization have enabled these techniques to remain competitive for many mold manufacturing applications. Proper selection of cutting tools, machining parameters, and workpiece holding methods is critical for achieving the required precision and surface quality.

Key Considerations in Conventional Machining

- Tool selection based on material properties and component geometry

- Optimal cutting parameters to balance productivity and tool life

- Workholding strategies to minimize deformation and ensure stability

- Surface finish requirements and how they influence machining operations

Computer Numerical Control (CNC) machining has revolutionized the mold manufacturing industry, enabling the production of highly complex and precise mold components. This section covers the principles, technologies, and applications of CNC machining in mold production, including CNC milling, turning, and multi-axis machining.

CNC Machining Technologies

3-Axis CNC Milling

The most common CNC machining process for producing flat and prismatic components.

5-Axis CNC Milling

Advanced machining technology enabling complex geometries and reduced setup times.

CNC Turning

Precision machining of rotational components with automated tool changes.

CNC Swiss Machining

High-precision machining of small, complex components with excellent accuracy.

CNC machining offers numerous advantages in mold manufacturing, including high precision, repeatability, and the ability to produce complex geometries that would be impossible or impractical with conventional methods. CAD/CAM software plays a critical role in CNC machining, translating design models into machine-readable instructions and optimizing tool paths for efficiency and quality.

CNC Programming

Understanding G-code and modern CNC programming techniques.

Toolpath Optimization

Strategies for efficient toolpath generation to reduce cycle times.

Special machining processes are essential for creating mold components with complex geometries, tight tolerances, and unique material properties. This section explores advanced special machining techniques such as Electrical Discharge Machining (EDM), Laser Cutting, and Electrochemical Machining (ECM).

EDM Processes

Removing material through controlled electrical discharges for high-precision applications.

Laser Machining

Using high-energy laser beams for precise cutting, welding, and surface treatment.

Electrochemical Machining

Material removal through electrochemical processes for complex shapes and hard materials.

Ultrasonic Machining

Utilizing ultrasonic vibrations for precision machining of brittle and hard materials.

Special machining processes are particularly valuable for mold manufacturing because they can handle hard materials, produce intricate details, and achieve excellent surface finishes. These techniques are often used in combination with conventional and CNC machining to create complete mold solutions.

Applications of Special Machining

- Machining of intricate mold cavities and cores

- Production of small, high-precision components

- Processing of hard and exotic materials

- Creating complex geometries and microstructures

In addition to conventional, CNC, and special machining processes, several other technologies play important roles in mold manufacturing. This section covers advanced processing technologies such as 3D printing, surface treatment, and finishing operations.

Emerging Technologies

Additive Manufacturing

3D printing technologies for rapid prototyping and production of mold components.

Surface Coating

Applying specialized coatings to improve wear resistance and release properties.

Heat Treatment

Thermal processing to enhance material properties and performance.

Electropolishing

Electrochemical finishing process for achieving smooth and precise surfaces.

These advanced technologies are transforming mold manufacturing by enabling faster prototyping, improved component performance, and reduced production costs. Additive manufacturing, in particular, is revolutionizing the industry by allowing the creation of complex geometries that were previously impossible or economically unfeasible.

3D Printing in Molds

How additive manufacturing is changing mold production.

Surface Engineering

Advanced techniques for enhancing mold surface properties.

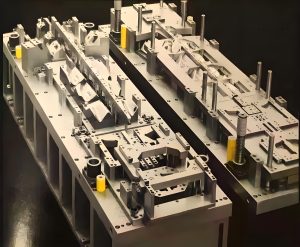

The assembly, installation, and debugging of molds are critical stages that determine the final quality and performance of the tool. This section provides insights into the best practices for mold assembly, proper installation procedures, and effective debugging techniques.

Mold Assembly Process

Component Preparation

Cleaning, inspecting, and preparing individual mold components for assembly.

Base Plate Installation

Mounting the base plates and ensuring proper alignment and flatness.

Core and Cavity Insertion

Precisely positioning and securing core and cavity inserts.

Ejection System Assembly

Installing and adjusting the ejection system components.

Final Inspection

Comprehensive检查 of the assembled mold for proper function and alignment.

Proper mold assembly requires meticulous attention to detail, precision measurements, and strict adherence to assembly guidelines. Effective debugging techniques are also essential to identify and resolve issues such as flash, short shots, or improper ejection before full production begins.

Alignment Techniques

Precision methods for ensuring proper mold component alignment.

Functional Testing

Procedures for testing mold performance before production.

The selection of appropriate materials and heat treatment processes is fundamental to achieving optimal mold performance and longevity. This section explores the various materials used in mold manufacturing and the critical role of heat treatment in enhancing their properties.

Tool Steels

Commonly used for mold components requiring high hardness and wear resistance.

Stainless Steels

Ideal for molds requiring corrosion resistance and polished surfaces.

Aluminum Alloys

Used for rapid prototyping and low-volume production due to their lightweight and machinability.

Heat Treatment

Processes such as quenching and tempering to improve hardness and durability.

The choice of mold material depends on several factors, including the type of molding process, the material being molded, production volume, and required surface finish. Heat treatment processes are used to modify the microstructure of the material, enhancing properties such as hardness, toughness, and wear resistance.

Key Material Properties for Molds

- Hardness and wear resistance

- Thermal conductivity

- Corrosion resistance

- Ductility and toughness

- Polishability and surface finish

Effective management and consideration of non-technical factors are essential for the success of any mold manufacturing project. This section covers critical aspects of mold manufacturing management, including project planning, quality control, cost management, and workforce development.

Key Management Considerations

Project Planning

Developing comprehensive project plans with clear milestones and timelines.

Cost Management

Strategies for controlling costs while maintaining quality and efficiency.

Quality Control

Implementing rigorous quality control measures throughout the manufacturing process.

Workforce Development

Training and developing skilled workers to meet industry demands.

Non-technical factors such as communication, collaboration, and adaptability also play significant roles in the success of mold manufacturing projects. Effective management practices ensure that projects are completed on time, within budget, and to the required quality standards, while fostering innovation and continuous improvement.

Lean Manufacturing

Applying lean principles to eliminate waste and improve efficiency.

Digital Transformation

Leveraging digital technologies for smarter manufacturing processes.

Ready to Transform Your Mold Manufacturing Processes?

Partner with our experts to implement industry-leading mold manufacturing technologies and practices.